The Fusing Current Calculator is a practical tool designed to Estimate Total Fusing Time, Energy, and Cost for Glasswork or Metalwork Projects.

Fusing Calculator – Instantly Estimate Total Fusing Time, Energy, and Cost for Glasswork or Metalwork Projects

Our team converts drinks into code — fuel us to build more free tools!

Formula used in Fusing Calculator

The calculator uses a straightforward formula to calculate the required fuse size:

Required Fuse Size = Current Rating + Safety Margin

The “Current Rating” is the amount of current that your circuit requires for normal operation, measured in amperes (A). The “Safety Margin” represents the additional current capacity added to account for unexpected variations or spikes in the circuit.

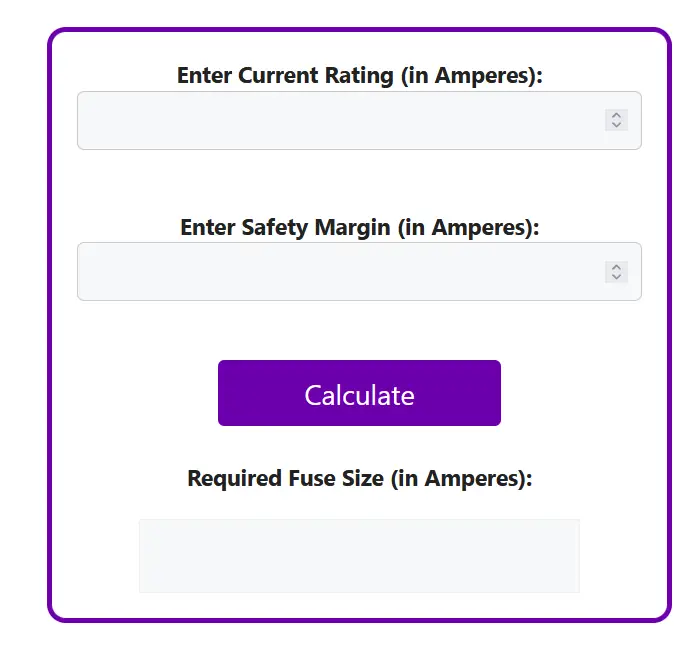

How to Use Fusing Calculator?

Using the Fusing Current Calculator is a straightforward process:

- Input the “Current Rating” of your circuit in amperes (A). This is the typical current required for the circuit to operate safely.

- Input the desired “Safety Margin” in amperes (A). This accounts for any unforeseen variations or spikes in the current.

- Click the “Calculate” button.

- The result displayed in the “Required Fuse Size” field represents the minimum fuse size needed for your circuit to operate safely.

Example of Fusing Calculator Calculation

Let’s illustrate the usage of the Fusing Current Calculator with an example:

Suppose you have a circuit with a current rating of 15A, and you want to add a safety margin of 5A to account for unexpected fluctuations. Using the calculator:

- Input 15 in the “Current Rating” field.

- Input 5 in the “Safety Margin” field.

- Click “Calculate.”

The calculator will determine that you need a minimum fuse size of 20A to ensure safe operation.

Table of various uses and Examples of Fusing Calculator

Consulting a table with various real-life examples of calculations done using a Fusing Current Calculator can provide a clear understanding of how this tool is applied in different scenarios.

Below is a table showcasing examples from various applications:

| Application | Circuit Current Rating (A) | Desired Safety Margin (A) | Calculation (Current Rating + Safety Margin) | Recommended Fuse Size (A) |

|---|---|---|---|---|

| Residential Lighting | 1.5 | 0.5 | 1.5A + 0.5A = 2A | 2A |

| Automotive Headlight | 5 | 1 | 5A + 1A = 6A | 10A |

| Home Air Conditioner | 15 | 3 | 15A + 3A = 18A | 20A |

| Laptop Charger | 0.8 | 0.2 | 0.8A + 0.2A = 1A | 1A |

| Industrial Conveyor Belt | 25 | 5 | 25A + 5A = 30A | 30A |

| Solar Panel System | 10 | 2 | 10A + 2A = 12A | 15A |

| Small Office Printer | 3 | 0.6 | 3A + 0.6A = 3.6A | 4A |

| Garden Water Pump | 8 | 1.6 | 8A + 1.6A = 9.6A | 10A |

This table illustrates how the Fusing Current Calculator can be used for a variety of applications, ensuring that the correct fuse size is selected to protect different electrical devices and systems. The safety margin is added to the normal operating current to provide a buffer for current fluctuations, and the next higher standard fuse size is chosen for optimal protection.

Different Types of Fuses and Their Applications

Understanding the different types of fuses and their specific applications is essential for ensuring electrical safety and circuit integrity. Fuses are critical components in preventing overcurrent and short circuit damage across various settings.

This guide focuses on the distinct characteristics and uses of three main types of fuses: cartridge fuses, commonly employed in industrial environments; blade fuses, frequently used in automotive systems; and glass fuses, often found in household electronics.

Each type is designed for particular current capacities and environments, making their correct selection and application vital for effective electrical protection.

Cartridge Fuses and Fusing Calculation Example

- Description: Cartridge fuses are cylindrical in shape and enclosed in a ceramic or glass tube. They are known for their reliability and are commonly used in industrial and high-current applications.

- Applications: Ideal for industrial electrical protection, they are often used in electrical panels, machinery, and air conditioning units. Due to their robust design, they are suitable for protecting against high current overloads.

Suppose you are working with an industrial machine that has a component requiring a constant current of 10 amperes (A) for normal operation. You need to select an appropriate cartridge fuse to protect this component.

Cartridge Fuses Fusing Calculator Calculation Steps

Determine the Current Rating:

- The current rating of the machine’s component is 10A. This is the normal operating current for which the fuse must allow without tripping.

Select a Safety Margin:

- For industrial applications, a common practice is to add a safety margin to account for potential surges or spikes. A safety margin of 25% is often recommended.

- Safety Margin = 25% of 10A = 2.5A.

Calculate the Required Fuse Size:

- Required Fuse Size = Current Rating + Safety Margin

- Required Fuse Size = 10A + 2.5A = 12.5A.

Select the Nearest Higher Standard Fuse Size:

- Since fuses are available in standard sizes, and it’s generally safe to round up, you would select the next higher standard size.

- Standard sizes might include 10A, 15A, 20A, etc.

- In this case, you would select a 15A cartridge fuse.

For a component that operates normally at 10A, a 15A cartridge fuse would be appropriate, considering a 25% safety margin. This ensures that the fuse can handle slight overloads without tripping, yet will still protect the equipment effectively against significant overcurrents.

Blade Fuses and Fusing Calculation Example

- Description: Blade fuses, recognized by their flat and compact design, have two prongs that fit into sockets. They are widely used due to their ease of installation and inspection.

- Applications: Predominantly used in automotive applications, they protect circuits in vehicles from overloads. Their varying color codes and sizes make it easy to identify the right fuse for different automotive systems.

Blade Fuses Fusing Calculator Example Scenario

Consider a scenario where a car audio system is designed to operate with a steady current flow of 8 amperes (A). To ensure the system’s protection and longevity, a blade fuse needs to be installed. The selection of the correct fuse size is crucial to prevent damage from potential overcurrent situations.

Blade Fuses Fusing Calculation Steps:

Establishing the Current Rating:

- The car audio system operates at a baseline current of 8A. This figure is critical as it represents the normal operational current demand of the system.

Incorporating a Safety Margin:

- For automotive electrical systems, it’s prudent to add a safety margin to the current rating. This accounts for possible fluctuations in current draw. A typical safety margin for such applications is around 20%.

- Calculating the Safety Margin: 20% of 8A equals 1.6A. This additional amount accounts for unexpected current surges that might occur during the audio system’s operation.

Total Fuse Size Calculation:

- The total required fuse size is determined by adding the safety margin to the current rating.

- Required Fuse Size = 8A (Current Rating) + 1.6A (Safety Margin) = 9.6A.

Selecting the Appropriate Fuse:

- Blade fuses are available in standard increments. Since a 9.6A fuse isn’t a standard size, the nearest higher standard size needs to be chosen.

- The closest higher standard fuse size in this category is typically a 10A fuse.

For the car audio system that has a normal operating current of 8A, a 10A blade fuse would be the most suitable choice. This selection includes a 20% safety margin, ensuring that the fuse will tolerate minor overcurrents without tripping unnecessarily, while still providing adequate protection against significant overloads.

Glass Fuses and Fusing Calculator Calculation Example

- Description: Glass fuses consist of a glass cylinder with metal caps on either end and a thin wire running through the middle. They offer the advantage of visual inspection for the fuse condition.

- Applications: Commonly used in household appliances and electronics, these fuses are suitable for low-current applications. They are perfect for devices like radios, televisions, and other consumer electronics where current overload protection is essential at a smaller scale.

Glass Fuses Fusing Calculator Example Scenario:

Imagine a household table lamp designed to operate with a typical current of 0.5 amperes (A). To safeguard this device, a glass fuse needs to be installed, ensuring protection against overcurrent situations.

Calculation Steps for Glass Fuses:

Determining the Current Rating for a Glass Fuse:

- The table lamp has a specified current rating of 0.5A, representing the normal operating current for the lamp.

Adding a Safety Margin:

- In household electronic applications, it’s advisable to include a safety margin to accommodate any slight increase in current. A common safety margin for such devices is 20%.

- Calculating the Safety Margin: 20% of 0.5A is 0.1A. This extra capacity is designed to handle minor fluctuations in current without causing the fuse to blow prematurely.

Calculating the Required Glass Fuse Size:

- The appropriate fuse size is found by adding the safety margin to the current rating.

- Required Fuse Size = 0.5A (Current Rating) + 0.1A (Safety Margin) = 0.6A.

Selecting the Suitable Glass Fuse:

- Glass fuses are also available in standard sizes. Given the calculated requirement, the closest higher standard size needs to be chosen.

- Typically, the nearest standard size for a fuse in this range would be 0.75A or 1A.

For a table lamp with a standard operational current of 0.5A, selecting a glass fuse with a rating of either 0.75A or 1A is advisable. This choice takes into account a 20% safety margin, ensuring the fuse can handle small current surges while still providing robust protection against significant overcurrent scenarios.

By understanding the specific types of fuses and their applications, you can ensure the appropriate selection for your electrical needs, enhancing safety and efficiency in your systems.

Additional Reading Material on Cartridge Fuses

For detailed information about cartridge fuses, you can refer to these sources:

- The GRL Official Site offers a comprehensive guide covering various types of cartridge fuses, their applications, specifications, installation best practices, operation, maintenance, and advantages compared to other technologies. You can find the guide here: Comprehensive Guide to Cartridge Fuse Types and Applications.

- Wikipedia provides an in-depth look at the working principles, construction, characteristics, and history of fuses in general, including information on the design and material of the fuse element, the rated current, time vs current characteristics, the I^2t value, and breaking capacity. For more information, visit: Fuse (electrical) – Wikipedia.

- All About Circuits offers a technical article that provides an overview of various fuse options available for low-voltage circuit designers. This includes a discussion on different types of fuses like axial, cartridge, surface mount, and PTC, along with their specific characteristics and applications. The article also compares resettable fuses (PTC fuses) with traditional fuses. To read this article, go to: The Many Types of Fuses: Axial, Cartridge, Surface Mount, PTC… – Technical Articles.

These sources collectively provide a well-rounded understanding of fuses, focusing on their types, applications, and operational principles, which should be beneficial for anyone seeking detailed information on this subject.

Fuse Ratings: Voltage, Current, Breaking Capacity, and Time Characteristics

Understanding fuse ratings is crucial for ensuring the safe and efficient operation of electrical systems. Fuse ratings are determined based on several key factors:

Fuse Voltage Rating:

The voltage rating of a fuse indicates the maximum voltage the fuse can safely handle. It’s essential that the fuse’s voltage rating is equal to or greater than the voltage of the circuit it’s protecting. Using a fuse with a voltage rating lower than the circuit voltage can lead to unsafe conditions, such as the fuse failing to clear the fault safely.

Fuse Current Rating:

This is the maximum current the fuse can carry without blowing. It’s determined by the fuse material and its dimensions. The current rating should be slightly higher than the normal operating current of the circuit but low enough to protect the circuit components from damage due to overcurrent conditions.

Breaking Fuse Capacity:

Also known as interrupting rating, this refers to the maximum current the fuse can safely interrupt without damage or hazard. It’s crucial in high-current circuits where the potential fault current can be very high. A fuse with a low breaking capacity used in a high-current circuit may fail to interrupt the fault, leading to possible damage or fire.

Time Characteristics (Slow Blow vs. Fast Blow Fuses):

- Fast Blow Fuses: These fuses respond quickly to overcurrent conditions. They are designed to protect sensitive electronic equipment that can be damaged by short-duration overloads. Their construction allows them to blow in fractions of a second upon detecting an overload.

- Slow Blow Fuses: Also known as time-delay fuses, these have a delayed response to overcurrent. This delay allows them to withstand temporary surges that are normal for certain electrical equipment (like motor starts) without blowing. They have a special construction, often with a spring or thicker element, allowing them to absorb short-term overloads.

Environmental Factors: Fuses are also rated based on their operating environment. Factors like temperature, humidity, and altitude can affect a fuse’s performance. Manufacturers provide derating guidelines to adjust the fuse ratings under different environmental conditions.

Physical Size and Shape: The physical dimensions of a fuse are also part of its rating, influencing its current-carrying capacity and how it dissipates heat.

Certification Standards: Fuses are tested and rated according to various standards (like UL, IEC) to ensure consistent performance across different brands and models.

Understanding these factors and selecting the correct fuse for a specific application is vital to protect electrical circuits from overcurrents, ensuring safety and reliability. This selection process involves assessing the normal operating conditions of the circuit and the potential fault scenarios, then choosing a fuse that matches these conditions while conforming to the relevant safety standards.

Fuse Safety Standards and Regulations: Understanding IEC and UL Compliance

Fuses are critical components in electrical systems, and they must adhere to specific safety standards and regulations to ensure they function correctly and safely. These standards are set by international regulatory bodies and are designed to provide guidelines for fuse design, testing, and application. Two of the most widely recognized standards are from the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL).

IEC Standards for Fuses

IEC 60269 Fuse Series: This is a set of standards that define the characteristics, performance requirements, and test methods for fuses intended to protect electrical installations and equipment. It covers a wide range of fuse types used in household, commercial, and industrial applications.

- IEC 60269-1: This part provides general requirements for all fuse types.

- IEC 60269-2: It focuses on fuses for household and similar applications.

- IEC 60269-3: This part is specific to industrial fuses and includes guidelines for their application and coordination.

UL Standards for Fuses

UL 248 Fuse Series: This series of standards, published by Underwriters Laboratories, outlines the requirements for low-voltage fuses. These standards are widely recognized in North America and are often referenced in international markets as well.

- UL 248-1: Provides general requirements applicable to all low-voltage fuses.

- UL 248-2 through UL 248-15: These parts provide specific requirements for different fuse types, such as plug fuses, cartridge fuses, and semiconductor fuses.

Common Features of Fuse Standards

- Performance Criteria: Standards specify how fuses should perform under various conditions, including overload and short-circuit scenarios.

- Environmental Considerations: They take into account how environmental factors like temperature and humidity can affect fuse performance.

- Safety Features: Standards ensure that fuses have features that enhance safety, such as breaking capacity and the ability to withstand voltage surges.

- Testing Methods: Detailed testing procedures are outlined to verify that fuses meet the specified requirements.

- Markings and Ratings: They define the necessary markings that should appear on fuses, including voltage and current ratings, interrupting rating, and standard compliance.

Importance for Professionals

For professionals involved in electrical design and installation, compliance with these standards is crucial for several reasons:

- Ensuring Safety: Compliance ensures that the electrical systems are safe for use and capable of protecting against electrical hazards.

- Regulatory Compliance: In many regions, adherence to these standards is a legal requirement.

- Reliability and Performance: Standards-compliant fuses ensure predictable and reliable performance in protecting electrical circuits.

Professionals should always refer to the latest versions of these standards, as they are periodically updated to reflect new technologies, materials, and safety research. Additionally, when working in specific regions or industries, it’s important to be aware of any local or sector-specific regulations that may apply.

Case Studies of Fusing Calculator Applications Across Industries

The Fusing Current Calculator is a versatile tool that has been effectively used in various industries to ensure the correct selection of fuses, enhancing safety and efficiency. Here are some case studies or real-world applications across different sectors:

Fusing Calculator in Automotive Industry:

- Application: In the automotive industry, the calculator is used for selecting fuses in vehicle electrical systems. For instance, when installing a new audio system or additional lighting in a car, the calculator helps determine the correct fuse size to protect these systems.

- Case Study Example: A car manufacturer may use the calculator to determine fuse sizes for new electronic components such as infotainment systems, GPS, or electric vehicle charging systems. By inputting the current rating of these components and a safety margin, they ensure that the fuses selected provide adequate protection without causing unnecessary interruptions.

Fusing Calculator in Electrical Sector:

- Application: Electricians often use the calculator when installing or upgrading home or commercial electrical systems. This can include adding new circuits for appliances or lighting.

- Real-World Example: In a home renovation project, an electrician might use the calculator to select the appropriate fuse size for a new air conditioning system. By inputting the system’s current requirements and considering a safety margin, they can choose a fuse that will safely interrupt excessive current flow.

Fusing Calculator in Manufacturing and Industrial Settings:

- Application: In manufacturing plants, the calculator is used to select fuses for machinery and production equipment.

- Case Study Example: A manufacturing facility may utilize the calculator when installing new production machinery. Given the machine’s power requirements and the operating conditions, the calculator assists in choosing fuses that can handle the machine’s normal operation and any potential overloads, thereby preventing equipment damage and downtime.

Fusing Calculator Use in Energy Sector:

- Application: The calculator is also valuable in the energy sector, particularly for renewable energy installations like solar panels or wind turbines.

- Real-World Example: For a solar panel installation, the calculator could be used to determine the appropriate fuse size for the inverter and the connection to the electrical grid. This ensures the system is protected against overcurrents caused by fluctuations in power generation or grid instability.

Fusing Calculator in Electronic Devices and Systems:

- Application: In the electronics industry, the calculator is crucial for selecting fuses for various electronic devices and systems.

- Case Study Example: An electronics manufacturer might use the calculator to determine the correct fuse size for a new consumer electronic product, like a gaming console or smart home device, ensuring the product’s safety and compliance with regulatory standards.

These examples illustrate how the Fusing Current Calculator plays an essential role in various industries by aiding in the correct fuse selection, thereby ensuring the safety and reliability of electrical systems and devices.

Common Pitfalls: How to Avoid Errors in Fuse Selection

Selecting the appropriate fuse for an electrical circuit is crucial for safety and functionality, yet common mistakes can often occur during this process. Here are some of these errors and how they can be avoided:

Over-Sizing Fuses:

- Mistake: Choosing a fuse with a current rating significantly higher than the circuit’s normal operating current can lead to inadequate protection. In such cases, the fuse may not blow in an overcurrent situation, risking damage to the circuit or electrical fire.

- Avoidance: Always select a fuse whose current rating is slightly above the circuit’s maximum operating current but low enough to protect against overcurrents.

Under-Sizing Fuses:

- Mistake: Using a fuse with a current rating too close to the circuit’s normal operating current can cause the fuse to blow frequently, even under normal conditions. This can lead to unnecessary downtime and replacements.

- Avoidance: Ensure that the fuse rating accommodates the circuit’s normal current plus a small margin. Utilize the fusing current calculator to determine the appropriate size, including a safety margin.

Selecting the Wrong Type of Fuse:

- Mistake: Using the wrong type of fuse (such as fast-acting instead of slow-blow for circuits with initial surges) can either lead to frequent fuse replacements or inadequate protection.

- Avoidance: Understand the characteristics of the circuit, such as whether it experiences initial surges (as in motor circuits) or requires immediate disconnection (as in sensitive electronic circuits). Choose the fuse type accordingly.

Ignoring Voltage Rating:

- Mistake: Overlooking the voltage rating of a fuse can lead to unsafe conditions. A fuse with a voltage rating lower than the circuit voltage may not be able to clear the fault safely.

- Avoidance: Always match or exceed the circuit’s voltage with the fuse’s voltage rating.

Neglecting Environmental Factors:

- Mistake: Failing to consider environmental conditions like temperature, which can affect fuse performance.

- Avoidance: Consider environmental conditions and choose fuses with appropriate temperature ratings or apply derating factors as necessary.

Disregarding Manufacturer’s Specifications and Standards:

- Mistake: Ignoring the specifications provided by manufacturers and relevant safety standards can lead to improper fuse selection.

- Avoidance: Refer to manufacturer’s data sheets and comply with industry standards for fuse selection.

Overlooking Aging of Fuses:

- Mistake: Not considering the aging factor of fuses, especially in circuits with frequent load fluctuations, can lead to unexpected failures.

- Avoidance: Regularly inspect and replace older fuses, and consider the aging factor in environments with variable loads.

By being aware of these common mistakes and taking the necessary steps to avoid them, professionals and individuals can ensure that they select the most appropriate fuse for their specific application, enhancing the safety and efficiency of their electrical systems.

Heading:

Fuses vs. Circuit Breakers: An In-Depth Comparison for Optimal Electrical Safety

When choosing between fuses and circuit breakers for electrical protection, it’s essential to consider the specific needs of your application. Here’s a more detailed comparison to help guide your decision:

Fuses | Advantages and Disadvantages

Advantages:

- Affordability and Simplicity: Fuses are generally more affordable and have a straightforward design with no moving parts, which translates to high reliability and minimal maintenance.

- Quick Response to Overcurrent: They react very fast to overloading, providing excellent protection, particularly for sensitive electronic equipment that cannot tolerate excessive current even for short periods.

- High Breaking Capacity: Fuses are capable of handling high-current fault conditions, making them suitable for applications where large fault currents are possible.

Disadvantages:

- One-Time Use and Replacement Needs: After a fuse blows, it must be replaced, which can be inconvenient, especially in critical operations where downtime is costly.

- No Immediate Indication of Trip: When a fuse blows, it doesn’t provide an immediate visual indication, which can make identifying the problem in a complex system more time-consuming.

- Fixed Trip Setting: Fuses are designed for specific current ratings and do not offer adjustable trip settings, necessitating accurate sizing for each application.

Circuit Breakers | Advantages and Disadvantages

Advantages:

- Reusability and Ease of Reset: Circuit breakers can be easily reset after tripping, eliminating the need for replacement and thus reducing long-term costs and maintenance.

- Clear Trip Indication: They provide an immediate visual or mechanical indication of a trip, aiding in quick diagnostics and restoration of power.

- Adjustable and Customizable Settings: Many circuit breakers allow for adjustable trip currents and delay settings, offering flexibility for various applications.

- Versatility and Manual Control: They can be used for manual switching of circuits, which is beneficial in maintenance and testing scenarios.

Disadvantages:

- Higher Initial Investment: The upfront cost of circuit breakers is typically higher than that of fuses, although this may be offset by their reusability.

- Complexity and Maintenance: With more components and moving parts, circuit breakers might require more maintenance and are potentially more prone to mechanical failure.

- Potential Delay in Response: Some types of circuit breakers may not react as quickly as fuses to overcurrent conditions, which could be a critical factor in protecting highly sensitive equipment.

Ideal Applications for Fuses and Circuit Breakers

- Fuses: Best suited for protecting sensitive electronics, residential or small commercial settings where high breaking capacity is essential, and in systems where operational simplicity is valued over the convenience of reset.

- Circuit Breakers: Preferred in larger commercial and industrial settings for their flexibility, in systems requiring frequent manual intervention, and where immediate restoration of power post-trip is crucial.

Understanding these differences is key to selecting the right protection device for your electrical system. The decision should be based on factors such as the nature of the load, the operating environment, maintenance capabilities, and safety requirements.

Both fuses and circuit breakers play critical roles in electrical safety, and the choice between them should align with the overarching objectives of reliability, safety, and efficiency in your electrical installations.

FAQs About Fusing Calculator

What is the purpose of adding a safety margin?

The safety margin ensures that the fuse can handle any unexpected current variations, providing an extra layer of protection for your circuit.

Is this Fusing Calculator suitable for both AC and DC circuits?

Yes, the Fusing Current Calculator is applicable to both AC and DC circuits.

Are there any limitations on the values I can input?

The calculator accepts positive numerical values for the current rating and safety margin. Ensure they are within the acceptable range for your application.

Can I use this Fusing Calculator for high-voltage applications?

The calculator is versatile and can be used for various voltage levels. However, always consult relevant safety standards and guidelines for high-voltage applications.

Is this calculator suitable for automotive fusing requirements?

Absolutely. This calculator is handy for determining fuse sizes in automotive electrical systems.

How accurate is the calculator’s result?

The calculator provides a basic estimation. For critical applications, it’s recommended to consult with a professional engineer.

Is Fusing Calculator free to use?

Yes, the Fusing Current Calculator is a free tool available for your convenience.

Where can I find more information on fuse selection and safety?

Consult industry standards, and manufacturer guidelines, or seek advice from qualified professionals.

Conclusion about Fusing Calculator

The Fusing Current Calculator is more than just a tool; it’s a vital asset in ensuring the safety and efficiency of electrical systems. By simplifying the complex task of fuse selection, this calculator aids engineers, electricians, and anyone working with electrical circuits in making precise and informed decisions.

Its ability to accurately determine the necessary fuse size, factoring in both the operational current and an additional safety margin, translates to enhanced protection for equipment and a significant reduction in the risk of electrical mishaps. T

his tool is indispensable in a wide range of settings, from industrial applications to everyday household uses, offering a level of convenience and reliability that is essential in modern electrical practices. By utilizing the Fusing Current Calculator, professionals and enthusiasts alike can confidently safeguard their electrical systems, ensuring they operate within safe parameters while maintaining optimal performance.